An Unbiased View of 24??media

An Unbiased View of 24??media

Blog Article

How 24??media can Save You Time, Stress, and Money.

Table of ContentsExcitement About 24??media24??media Things To Know Before You Buy24??media Things To Know Before You Get This9 Easy Facts About 24??media Shown24??media Things To Know Before You Buy

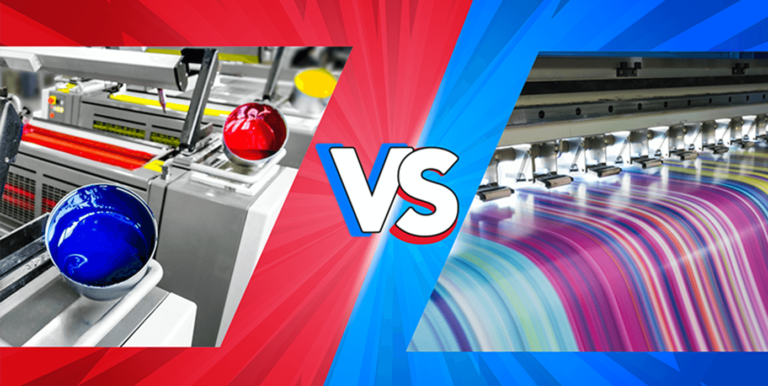

Advancements in print technology are changing the communications playing field when it comes to high quality, price and cutting-edge abilities. Countered printing and electronic printing are the major procedures through which print jobs are carried out both using four-color printing methods. Each alternative has its benefits, using different strategies to satisfy the demands of diverse production projects.

Usually, this has actually been the most consistent technique for specifically keeping shade matches, making it optimal for print runs that just need fixed printing such as pre-printed forms, sales brochures, flyers, calling card, and mass postcard mailings. However, because of the fixed nature of litho printing, it is not excellent for variable print pieces that will certainly be sent by mail to individual recipients such as declarations, letters, and personalized postcards.

24??media - Questions

The latest developments in print technology are helping to bring numerous of offset's advantages into the digital printing globe absolutely transforming the face of modern-day printing! There are some essential differences between Offset Printing and Digital Printing.

Today's electronic print equipment is amongst the most cutting-edge on the marketplace. Below are several of the greatest benefits of making use of electronic printing: control the electronic print room, with full-color printing finished in one procedure and seamlessly published directly from a print data. Without a prolonged set-up process, the calibration time of a certain job is reduced, adding to quicker print time and overall shipment.

The inkjet printing process has actually assisted to transform the sector along with the quality and rate of the output. The most recent inkjet modern technology can publish on standard offset supplies with dull, silk, and shiny finishes. High-grade digital print combined with software-managed shade administration practices includes optimum value to publish pieces and makes manufacturing procedures extra reputable than countered.

Not known Facts About 24??media

(https://www.huntingnet.com/forum/members/za24media.html?simple=1#aboutme)

Eco-friendly and biodegradable inks and toners are likewise offered for more sustainable printing. Digital print likewise gets rid of the need to wash plates or blankets with damaging chemicals at the end of the printing procedure.

Variable information helps businesses reach their precise customers and audience with uniquely-created and customized material. As modern technology enhances, the quality of digital printing has actually become second-to-none, with higher detail, color match capabilities and overall accuracy. Without the demand to wash plates or use excess ink, digital printing is additionally less wasteful and usually a lot more ecologically friendly.

("flexo"), include numerous make-ready actions to transfer an initial photo to a substratum.

The Greatest Guide To 24??media

Digital printing, with less relocating pieces, is more dexterous than balanced out in this respect.

It's a method to mix your product packaging and marketing techniques. Lowered set-up time saves money on the front end. And because these are not large bulk orders, smaller services can afford to publish without needing to fulfill the higher and more pricey print thresholds of traditional printing. Digital printing assists secure your brand name against counterfeiting by integrating obvious and concealed remedies on your product packaging.

Make sure you work together with a printing and packaging partner that has the right qualifications. While eleventh-hour printing and customization are a massive advantage, electronic may not always be the very best approach for you. Counter printing has the benefit of cost-effectiveness with big print runs, especially those with sophisticated attractive results and specialized layers.

The Buzz on 24??media

Lithographic presses make use of 2 print platesa favorable and a negativeto transfer top quality color graphics onto an appropriate substrate. The favorable plate, with its smooth surface, brings in oil-based inks and drives away water. In comparison, the negative plate, with its harsh appearance, absorbs water and drives away oil. Rubber rollers are after that made use of to transfer the photo from the plate to the corrugated surface.

Corrugated paper can in some cases prove to be a tough surface to publish on, however Litho prints to a separate surface and is then laminated flooring to it, making it simple to publish high-grade images. It can be exceptionally constant, even for futures. As a matter of fact, the extra you print, the more affordable the prices become for Litho.

If you have enough time and budget, and a big quantity of a solitary layout, after that there should not be a concern. What Litho doesn't give you is exactly what Digital does, customization. More have a peek here on that particular later. Expensive established Longer turn-around No Variable Information Printing Smaller shade range, colors can be much less bright Digital printing is the procedure of printing electronic pictures straight onto the corrugated substrate using a single-pass, direct-to-corrugate technique - Stickers.

Report this page